Sikatack Panel 50 600ml (497834) – 20pcs/box

£816.20 +VAT

Price for 1 box (contains 20pcs)

Unit : 1 box

This system is designed to withstand extreme dynamic loads and dynamic conditions. Once cured this adhesive remains permanently elastic to accommodate differing thermal expansion of various building substrates. It eliminates stress fatigue at corners of panels and prevents cold bridging.

The adhesive is suitable for fixing:

- composite, Ceramic, High Pressure Laminate, Cement Based Cladding Panels, Most Metal and Powder Coated Substrates

Out of stock

SikaTack® Panel-50 is a one-part, non-sag silicone adhesive with a paste-like texture. It is used for structural joints in ventilated facades and interior wall cladding, where there will be static and dynamic stresses and high facade temperatures. The adhesive cures when it is exposed to atmospheric moisture to create a long-lasting elastomer. SikaTack® Panel-50 is a crucial component of the SikaTack® Panel system, which is designed for concealed, cost-effective fixing of ventilated facades.

- Elastic fixing system, vibration and movement absorbing

- Provides creative opportunities for facade design

- Withstands high dynamic and static stresses and elevated facade temperatures

PRODUCT BENEFITS

- Elastic fixing system, vibration and movement absorbing

- Provides creative opportunities for facade design

- Withstands high dynamic and static stresses and elevated facade temperatures

- Uniform tension over the whole facade

panel (no stress points) - 1-component product, ready to use

- Outstanding UV and weathering resistance

- Bonds well to a wide variety of substrates

Usage

SikaTack® Panel-50 is appropriate for structural joints in ventilated facades and interior wall cladding, connecting the panel subjected to dynamic and static stresses and elevated facade temperatures to the vertically installed substructure. The product is compatible with substrates such as anodised and coated aluminium, glass, metal composite, high-pressure laminate, and ceramics. This product is intended for experienced professional users only. Adhesion and material compatibility tests must be conducted on actual substrates and conditions to ensure effectiveness.

Packaging

| Unipack | 600 ml |

Typical Product Data

| Chemical base | 1-component silicone | |

| Colour (CQP001-1) | Grey | |

| Cure mechanism | Moisture-curing

|

|

| Density (uncured) | 1.4 kg/l

|

|

| Non-sag properties (CQP061-4 / ISO 7390) | Good | |

| Application temperature | ambient

|

5 ─ 40 °C

|

| Skin time (CQP019-1) | 25 minutes A

|

|

| Curing speed (CQP049-1) | (See diagram)

|

|

| Shore A hardness (CQP023-1 / ISO 48-4) | 38

|

|

| Tensile strength (CQP036-1 / ISO 527) | 2.1 MPa

|

|

| Elongation at break (CQP036-1 / ISO 527) | 450 % | |

| Tear propagation resistance (CQP045-1 / ISO 34) | 7 N/mm | |

| Service temperature | -40 ─ 150 °C | |

| Shelf life | 9 months B

|

| CQP = Corporate Quality Procedure | A) 23 °C / 50 % r. h. | B) storage below 25 °C |

Application

Surface Preparation

The cleanliness and dryness of surfaces are essential to achieve a long-lasting bond, therefore grease, oil, and dust must be completely removed. Additionally, the treatment required for the surface depends on the specific properties of the substrate, and it is crucial to ensure a durable bond.

Application

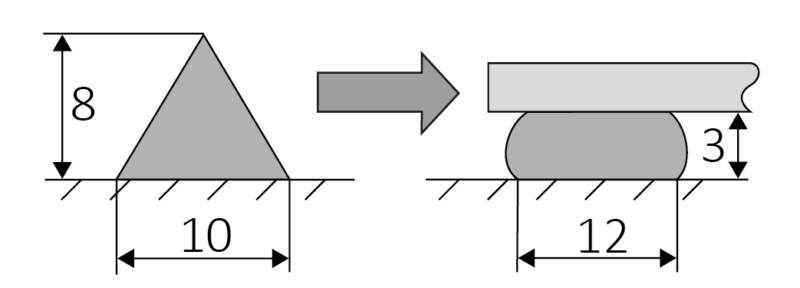

The standard geometry for bonding façade panels is at least 12 x 3 mm. The supplied nozzle (10 x 8 mm) ensures proper dimension of the compressed bead (see figure below).

The ideal temperature range for applying the adhesive is between 15°C and 25°C, and it should not be used at temperatures below 5°C or above 40°C. To prevent condensation, the temperature of the bonding components should be at least 3°C higher than the dew point of the air. Skin time may be shorter in hot and humid conditions. The panel should be installed within 75% of the determined skin time under local climate conditions. Never join bonding parts if the adhesive has formed a skin. SikaTack® Panel-50 can be applied using hand, pneumatic, or electric driven piston guns.

Removal

To clean tools and equipment from uncured SikaTack® Panel-50, use Sika® Remover-208 or a compatible solvent. Once cured, the material can only be removed mechanically.

If SikaTack® Panel-50 gets on your skin, wash the area immediately using hand wipes like Sika® Cleaner-350H or an appropriate industrial hand cleaner with water. Do not use solvents on your skin.

| Weight | 0.65 kg |

|---|

Related products

Sika Products

Sika Products

Sika Products

Sika Products

Sika Products

Sika Products

Sika Products