Sikaflex 545 – 20pcs/box (600ml)

£346.00 +VAT

High initial grab STP assembly adhesive

Sikaflex-545 is a low emission 1-component silane Terminated Polymer (STP) assembly adhesive. it has a unique high initial grab with high load capacity and excellent workability. It bonds well to a wide range of substrates with minimal pre-treatment.

SIKAFLEX 545 – Price for one box (contains 20pcs)

1pcs: 600ml

Unit : 1 box

Sikaflex®-545

Advantages:

- Powerful initial grab

- Very low emission

- Bonds well to a wide variety of substrates without the need for special pre-treatment

Unit : Each

USAGE

Sikaflex®-545 is specifically formulated to provide strong initial adhesion and can be used on a wide range of substrates, such as wood, glass, metals, ceramics, and plastics. However, it is recommended to consult the manufacturer and perform compatibility tests on the original materials before using Sikaflex®-545 on materials prone to stress cracking. It should only be used by experienced professionals and tested on actual substrates and conditions to ensure proper adhesion and material compatibility.

PRODUCT BENEFITS

- Powerful initial grab

- Very low emission

- Bonds well to a wide variety of substrates without the need for special pre-treatments

- Excellent workability

- Free of isocyanate, solvent and phthalate

- Meets highest EHS standards

- EC1 certificate

SIKAFLEX 545 APPLICATION INFORMATION

Surface Preparation

The surfaces to be bonded must be thoroughly cleaned, dried, and free from any contaminants such as grease, oil, and dust. The surface treatment required will depend on the specific characteristics of the substrates and is crucial to ensure a durable bond. The recommended surface preparation methods can be found in the current version of the relevant Sika® Pre-treatment Chart. However, it should be noted that these recommendations are based on past experience and must be verified through testing on the actual substrates.

Application

Use a suitable caulking gun to apply the adhesive, taking care to avoid any air pockets in the joint. Sikaflex®-545 can be applied at temperatures ranging from 5°C to 40°C, but changes in its reactivity and application properties should be taken into account. The ideal temperature for the substrate and sealant is between 15°C and 25°C.

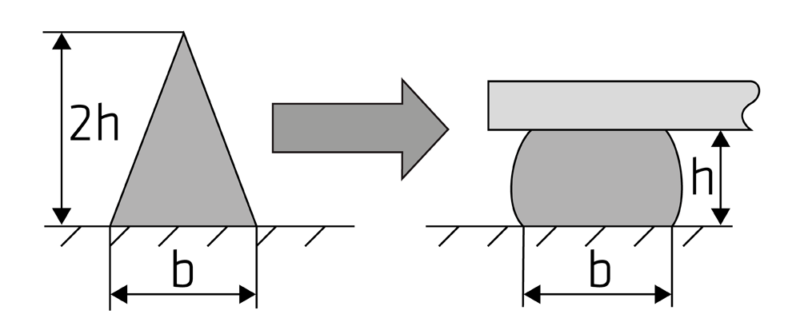

It should be noted that the viscosity of the adhesive will increase at lower temperatures, so it is recommended to condition it at ambient temperature prior to use for easier application. To ensure an even bondline thickness, it is suggested to apply the adhesive in a triangular bead shape (refer to figure 1).

Figure 1: Recommended bead configuration

Sikaflex®-545 can be processed with manual, pneumatic or electric driven piston guns as well as pump equipment. The open time is significantly shorter in hot and humid climate. The parts must always be installed within the open time. Never join bonding parts if the adhesive has built a skin.

Tooling and finishing

Tooling and finishing should be completed within the designated skin time of the adhesive. It is advisable to use Sika® Tooling Agent N for this purpose. Before using other finishing agents, it is essential to test their suitability and compatibility with the adhesive.

Removal

Sikaflex®-545 can be cleaned from tools and equipment using Sika® Remover-208 or an appropriate solvent before it cures. However, once it has cured, it can only be removed by mechanical means. It is crucial to wash any exposed skin and hands immediately using hand wipes like Sika® Cleaner-350H cleaning towels or a suitable industrial hand cleaner with water. Do not use solvents on skin.

Overpainting

The ideal time to paint Sikaflex®-545 is within the skin formation period. If painting is carried out after the sealant has formed a skin, adhesion can be improved by treating the joint surface with Sika® Aktivator-100 or Sika® Aktivator-205 before painting. For paints that require baking at a temperature of more than 80°C, the sealant should be allowed to cure entirely before painting. All paints should be tested in preliminary trials under manufacturing conditions. Typically, the elasticity of paints is lower than that of sealants, which can lead to paint cracking in the joint area.

| Weight | 0.65 kg |

|---|

Related products

Sika Products

Sika Products

Sika Products

Sika Products

Sika Products

Sika Products

Sika Products